A1610 BondVisor - Mechanical Impedance Analysis (MIA) Instrument

The instrument for non-destructive testing bonded or laminated components by Mechanical Impedance Analysis (MIA)

Product Description

A1610 BondVisor is a handheld instrument for detecting delaminations and other material defects by manually scanning the inspection area. Changes in mechanical impedance created by defects and imperfections in laminated materials and honeycomb structures. The coupling of the sensor is done dry without coupling liquid. The constant pressure of the spring-loaded sensor guarantees stable and reliable indications.

Special features

- Rapid start: new operators do not need extensive training

- Easy calibration: in-field automatic sensor calibration on the inspection object

- Stable and reliable operation on rough/uneven surfaces due to spring-loaded sensor design

- Customized sensor design for specific material combinations can be provided on a bilateral agreement basis

Application

The main application field of the A1610 BondVisor is the non-destructive testing of laminated components and bondings.

The instrument is applicable for the following materials and material combinations:

- Multilayered laminates

- Fiber-laminate materials

- Laminate-honeycomb bonding

- Laminate-metal bolding

- Metal-metal bonding

- Metal soldering

- Metal-feltmetal brazing

- Foams (hard and soft)

- Wood laminates

Possible sources of material defects:

- Impact damages by foreign objects

- Hail & lightning strikes

- Loss of strength caused by heat

- Thickness variations

- Osmosis damages of fiberglass boats

Specification

| Measurement principle | Mechanical Impedance Analysis (MIA) |

| Inspection range by two MIA transducers | 0.15 mm to 13 mm / 0.006 to 0.5 inches (depending on material properties) |

| Flaw detection capability |

For laminated components: > dia 8 mm / 0.3 inch For metal alloy bondings: > dia 0.5 mm / 0.02 inch with the sizing accuracy < 25% |

| Transmitter type | Pulse excitation |

| Electronic unit dimensions |

159 x 77 x 35 mm 6.3 x 3 x 1.4 inches |

| Weight | 0.3 kg / 0.66 lbs |

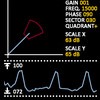

| Display | 2.4-inch color display 240x320 TFT |

| Battery type | 3 x NiMH accu/battery with ³ 2.700 mAh |

| Battery operation time | up to 20 hours |

|

PC interface |

USB (for loading user pre-sets) |

| Environmental conditions |

Air temperature range: 10 to 50 °C / 50 to 122 °F Humidity: up to 98% (at 20 °C) |

Delivery kit

| Electronic unit | 1 |

| Single-element MIA transducer | 1 |

| Dual-element MIA transducer | 1 |

| Reference block Co-91 | 1 |

| Exchangeable NiMH battery | 3 |

| USB data cable | 1 |

| Flash drive with recovery | 1 |

| Power supply | 1 |

| Warranty certificate | 1 |

| Hard case | 1 |

Download

About ACS Group

Acoustic Control Systems – ACS Group – Established in 1991 – is the International Provider of Innovative Ultrasonic Testing Equipment and Professional Inspection and Engineering Services.

The definitive distinction of ACS products is their high technological level and ease of use, matching the requirements of professional users in a wide range of practical applications. The main goal of our instruments is to reach top technical characteristics by affordable costs in combination with the perfect warranty service and methodical support of our customers.

More than 30 years of in-field testing experience in combination with scientific signal and image processing techniques and modern manufacturing processes by using the best components available on the market allow ACS to be always technologically one step ahead of competitors.

Your email address will not be published. Required fields are marked *

Get a quote