Ultrasonic testing of construction materials is a well- established methodology for obtaining information on the strength and uniformity of concrete, rock, composites, ceramics, wood and refractory materials. It provides detecting defects such as voids, honeycombs, delaminations and cracks. Besides, ultrasonic mapping allows three- dimensional tomographic imaging objects, such as pipes, post-tensioning and precise measuring the thickness of elements. “Acoustic Control Systems – ACS Group” is the inventor of the modern ultrasonic instrumentation for concrete quality assessment and offers the most advanced range of ultrasonic imaging and testing solutions.

The equipment for non-destructive ultrasonic testing of concrete can be subdivided in three major groups:

Ultrasonic pulse-echo tomography systems

Non-destructive testing of concrete by means of ultrasound is the leading technology for assessment of structural integrity and localization of defects and voids in concrete and rock as well as for evaluation of the compressive strength by ultrasonic pulse velocity testing.

Ultrasonic pulse velocity testers (UPVT)

Non-destructive testing of concrete by means of ultrasound is the leading technology for assessment of structural integrity and localization of defects and voids in concrete and rock as well as for evaluation of the compressive strength by ultrasonic pulse velocity testing.

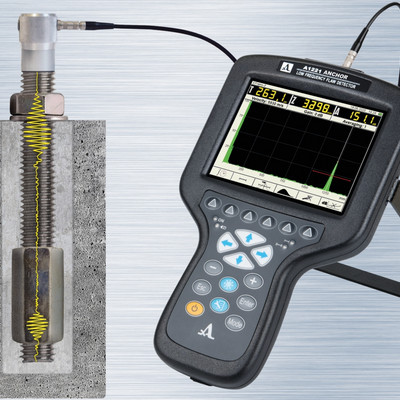

Ultrasonic pulse-echo flaw detectors

Non-destructive testing of concrete by means of ultrasound is the leading technology for assessment of structural integrity and localization of defects and voids in concrete and rock as well as for evaluation of the compressive strength by ultrasonic pulse velocity testing.